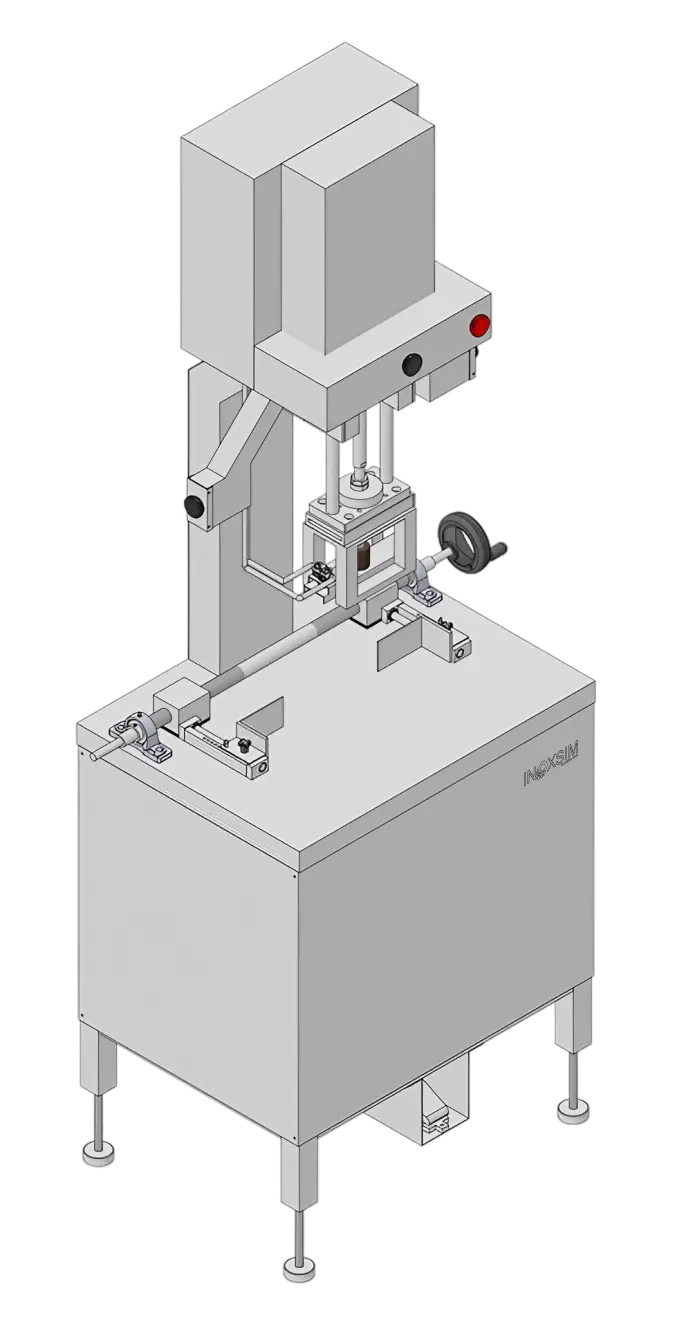

The ACM2560 machine is specialised equipment for safely opening and closing individual stainless steel moulds fitted with 1 to 4 springs and lateral fixing racks.

Its versatile design allows working with moulds of different dimensions without the need to change tools, thanks to its quick adjustment systems that adapt the fixing points to any required type and shape (within the measurements specified in this technical data sheet).

The compression of the springs is adjustable according to the specific needs of each production, considering both the volume of the food and the cooking and moulding requirements. One tool presses the lid arm, and another its base, which presses its surface to flatten the food. This achieves product flatness and uniformity of spring and rack compression.

The machine effectively compresses food before cooking, pressing the springs and lid to promote uniform compaction and binding of the product, reducing wastage during slicing.

Its versatile design allows working with moulds of different dimensions without the need to change tools, thanks to its quick adjustment systems that adapt the fixing points to any required type and shape (within the measurements specified in this technical data sheet).

The compression of the springs is adjustable according to the specific needs of each production, considering both the volume of the food and the cooking and moulding requirements. One tool presses the lid arm, and another its base, which presses its surface to flatten the food. This achieves product flatness and uniformity of spring and rack compression.

The machine effectively compresses food before cooking, pressing the springs and lid to promote uniform compaction and binding of the product, reducing wastage during slicing.