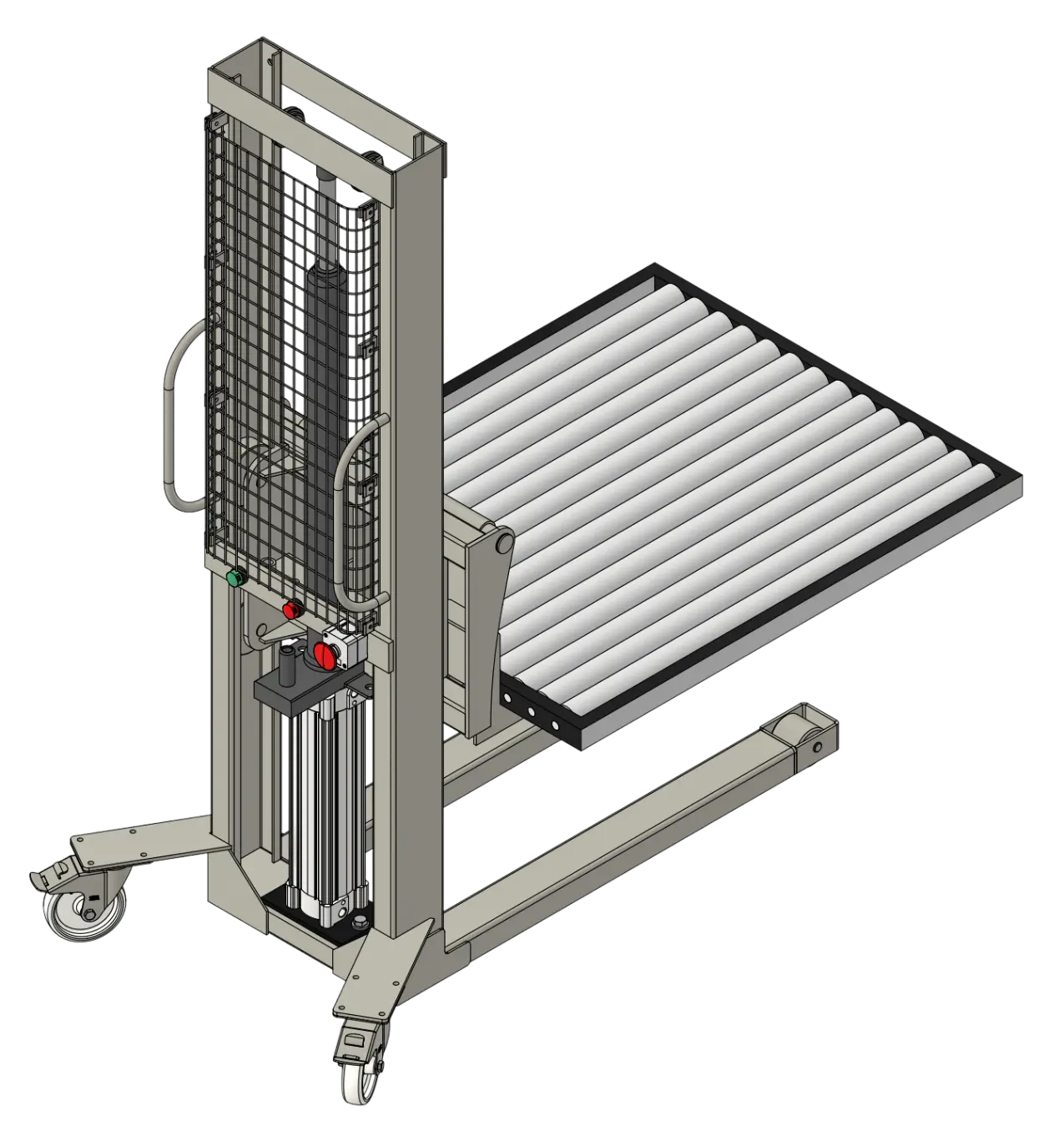

The AXEL200-1000 equipment is a mobile pallet truck unit equipped with omnidirectional castors and integral braking system. It enables controlled vertical displacement of a specialised upper platform with high-resistance sliding base, designed for safe transport of both full and empty moulds.

The platform incorporates optimally inclined rollers ensuring automatic mould retention in final position, maintaining permanent contact with the rear safety rail. This rail is fully retractable, facilitating rear loading and unloading operations without manual mould manipulation.

The lifting system enables intermediate positioning via vertical displacement selector lever, offering operational flexibility to adapt to different working heights according to specific mould loading or unloading requirements at various industrial process stations. The robust construction ensures reliable performance in demanding food processing environments with enhanced productivity and operational safety throughout extended operational cycles.

The platform incorporates optimally inclined rollers ensuring automatic mould retention in final position, maintaining permanent contact with the rear safety rail. This rail is fully retractable, facilitating rear loading and unloading operations without manual mould manipulation.

The lifting system enables intermediate positioning via vertical displacement selector lever, offering operational flexibility to adapt to different working heights according to specific mould loading or unloading requirements at various industrial process stations. The robust construction ensures reliable performance in demanding food processing environments with enhanced productivity and operational safety throughout extended operational cycles.