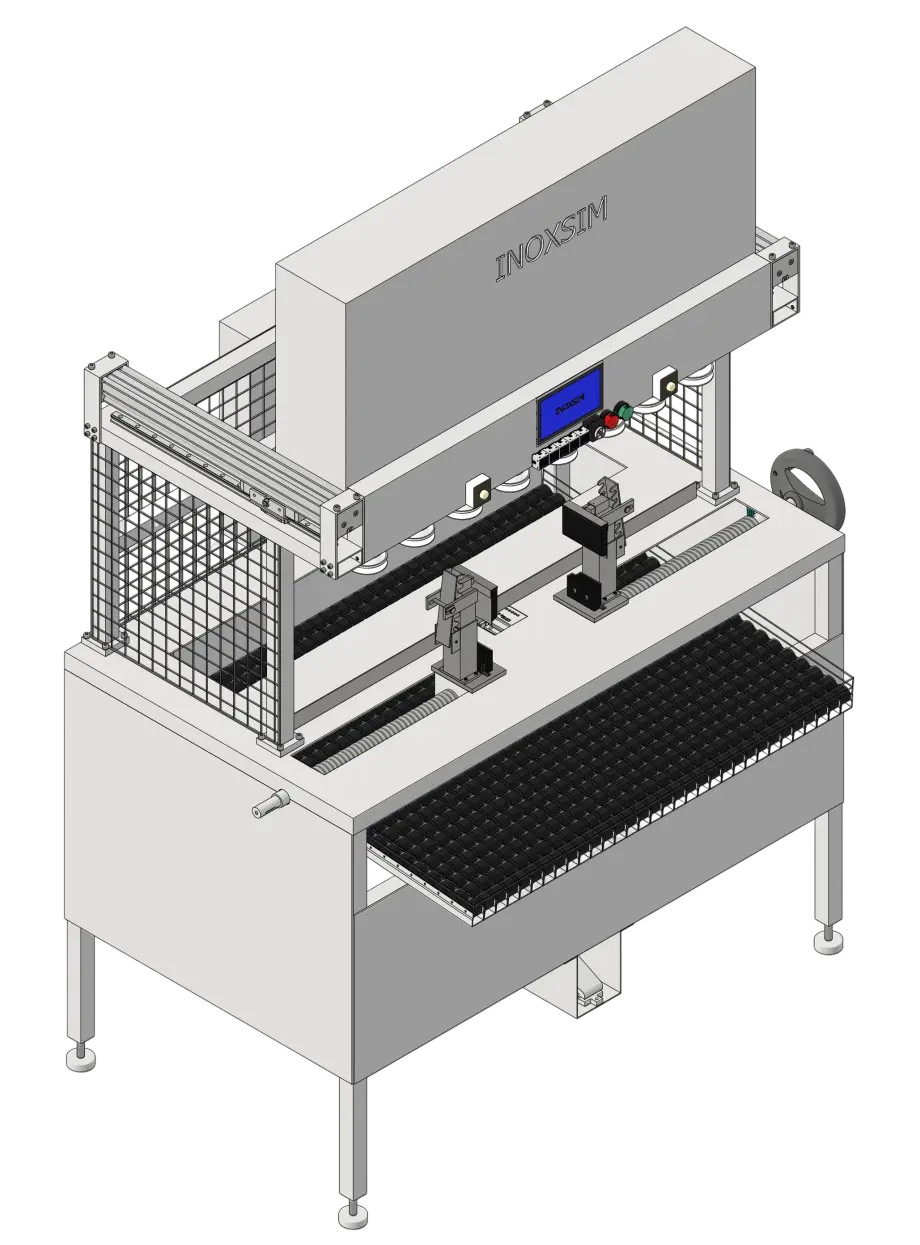

The DMIM20M105 machine is semi-automatic demoulding equipment designed to process one or several moulds simultaneously, within specified dimensional parameters.

It incorporates three-dimensional adjustable fixturing (X,Y,Z) with simple adjustment for precise mould clamping, achieving manual settings in under 50 seconds. Its versatility enables multiple configurations: processing single 1100mm moulds or up to four 250mm moulds mounted in series, maximising productivity.

The demoulding system operates via high-efficiency suction cups with autonomous vacuum generation by venturis, applying controlled suction to plastic wrappers of cooked and cooled food products.

Number, size, and position of suction cups are fully adjustable without tools using pins and rapid pneumatic connectors. It incorporates selectable hybrid vacuum and blow system, enabling alternative demoulding for products with damaged wrappers through position inversion and vertical extraction. Digital control system records cycles, schedules, production, and deviations.

It incorporates three-dimensional adjustable fixturing (X,Y,Z) with simple adjustment for precise mould clamping, achieving manual settings in under 50 seconds. Its versatility enables multiple configurations: processing single 1100mm moulds or up to four 250mm moulds mounted in series, maximising productivity.

The demoulding system operates via high-efficiency suction cups with autonomous vacuum generation by venturis, applying controlled suction to plastic wrappers of cooked and cooled food products.

Number, size, and position of suction cups are fully adjustable without tools using pins and rapid pneumatic connectors. It incorporates selectable hybrid vacuum and blow system, enabling alternative demoulding for products with damaged wrappers through position inversion and vertical extraction. Digital control system records cycles, schedules, production, and deviations.