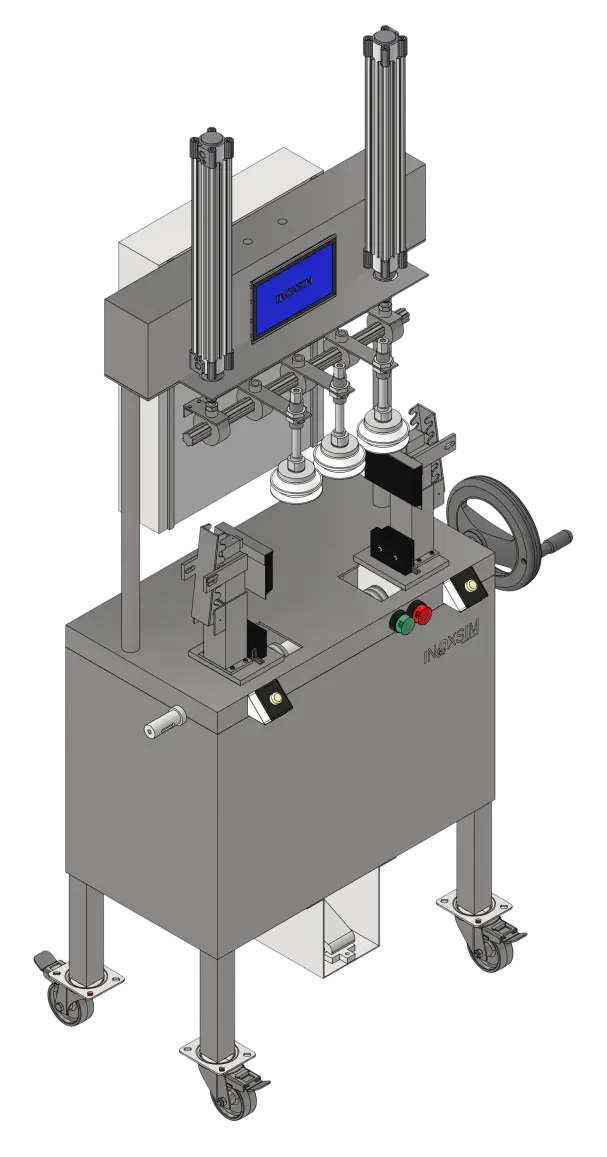

The DMIF-2045 Machine delivers advanced semi-automatic demoulding technology specifically engineered for manufacturing operations requiring precise handling of diverse individual mould configurations. This innovative system features sophisticated quick-adjust tooling capabilities that minimize changeover times between different mould types, providing exceptional operational flexibility without compromising accuracy or production quality. The integrated self-generated vacuum technology ensures reliable, consistent grip across various mould geometries and material compositions, eliminating the need for auxiliary vacuum equipment. Designed for operational simplicity and energy efficiency, the DMIF Machine operates using only standard compressed air (4-6 bars) and a conventional 220V power connection, making installation straightforward with minimal infrastructure modifications. With an impressive cycle time under 10 seconds, this system significantly enhances production throughput while maintaining strict quality standards. The ergonomic design reduces operator fatigue while maximizing workplace safety, making the DMIF Machine an ideal solution for industries including automotive components, medical devices, electronics manufacturing, and consumer products where versatility, reliability, and production speed are essential competitive advantages.