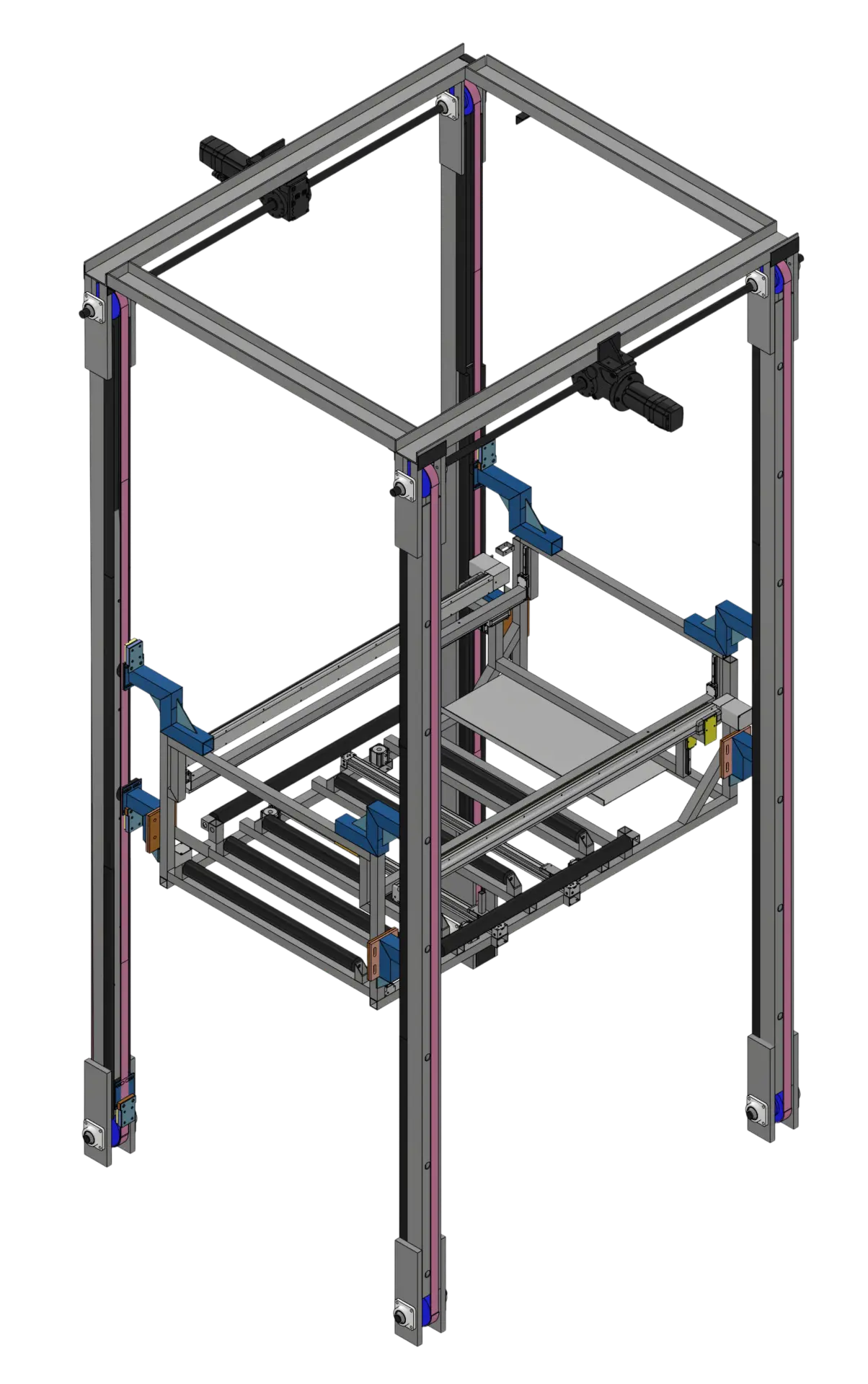

The EXEL200-1800 equipment is a semi-automatic lifting and extraction system for moulds from multi-mould towers.

Comprising four floor-mounted pillars with upper servomotor controlling vertical displacement of the extractor and mould-carrying platform, sliding vertically along integrated rails. The extractor mechanism performs automatic horizontal movements to secure moulds from each level, removing them through combined horizontal and vertical movements until positioning on the roller platform. Operation is controlled via operator-managed control panel, automatically activating horizontal displacement upon reaching the designated mould level. Following extraction, the platform automatically returns to base position for lateral discharge.

The system incorporates retractable wheel base between roller plane that elevates to enable mould rolling, utilising pusher tool for external displacement. This automated system ensures efficient multi-level mould extraction with minimal manual intervention, optimising productivity in industrial food processing applications.

Comprising four floor-mounted pillars with upper servomotor controlling vertical displacement of the extractor and mould-carrying platform, sliding vertically along integrated rails. The extractor mechanism performs automatic horizontal movements to secure moulds from each level, removing them through combined horizontal and vertical movements until positioning on the roller platform. Operation is controlled via operator-managed control panel, automatically activating horizontal displacement upon reaching the designated mould level. Following extraction, the platform automatically returns to base position for lateral discharge.

The system incorporates retractable wheel base between roller plane that elevates to enable mould rolling, utilising pusher tool for external displacement. This automated system ensures efficient multi-level mould extraction with minimal manual intervention, optimising productivity in industrial food processing applications.