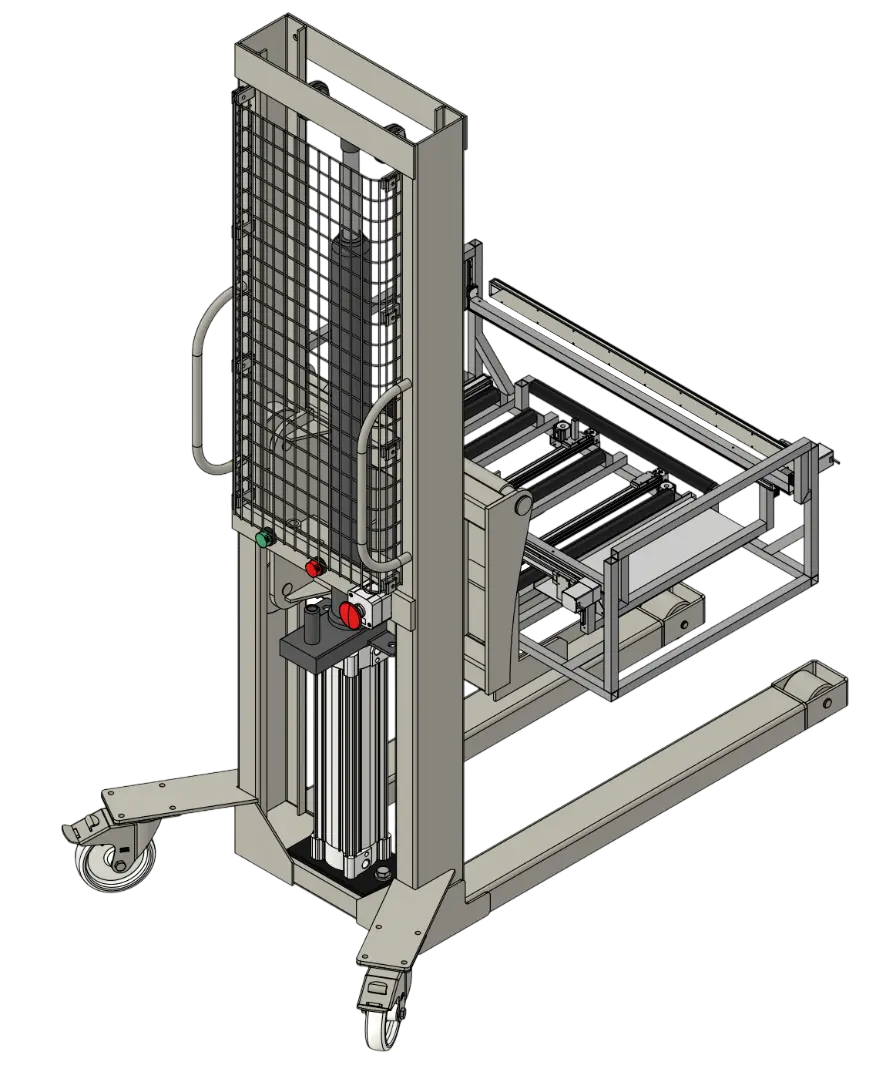

The EXEL200-1700 equipment is a mobile pallet truck unit equipped with omnidirectional castors and integral braking system. It enables controlled vertical displacement of a specialised upper platform with high-resistance sliding base, designed for safe transport of both full and empty moulds.

The system incorporates automated pneumatic extractor with specialised gripper for precise positioning opposite mould levels to be discharged from multi-mould towers. Positioning operation to contact point between gripper and moulds is performed via operator-controlled manoeuvring lever. The gripper extractor automation executes combined horizontal and vertical movements, removing moulds from cage and positioning them on roller platform.

For automatic discharge it incorporates retractable wheel base between roller plane that elevates to enable mould rolling, utilising pusher tool for external displacement. This integrated system ensures efficient multi-level mould extraction with enhanced automation and minimal manual intervention throughout operational cycles.

The system incorporates automated pneumatic extractor with specialised gripper for precise positioning opposite mould levels to be discharged from multi-mould towers. Positioning operation to contact point between gripper and moulds is performed via operator-controlled manoeuvring lever. The gripper extractor automation executes combined horizontal and vertical movements, removing moulds from cage and positioning them on roller platform.

For automatic discharge it incorporates retractable wheel base between roller plane that elevates to enable mould rolling, utilising pusher tool for external displacement. This integrated system ensures efficient multi-level mould extraction with enhanced automation and minimal manual intervention throughout operational cycles.