Holistic workflows

Exponential results

Every step matters. Our holistic workflow shapes automation solutions that enhance your complete food processing journey.

Analysis & Discovery

Deep immersion in your processes reveals opportunities for meaningful change.

Client-focused design

Engineering precision meets practical needs through collaborative design.

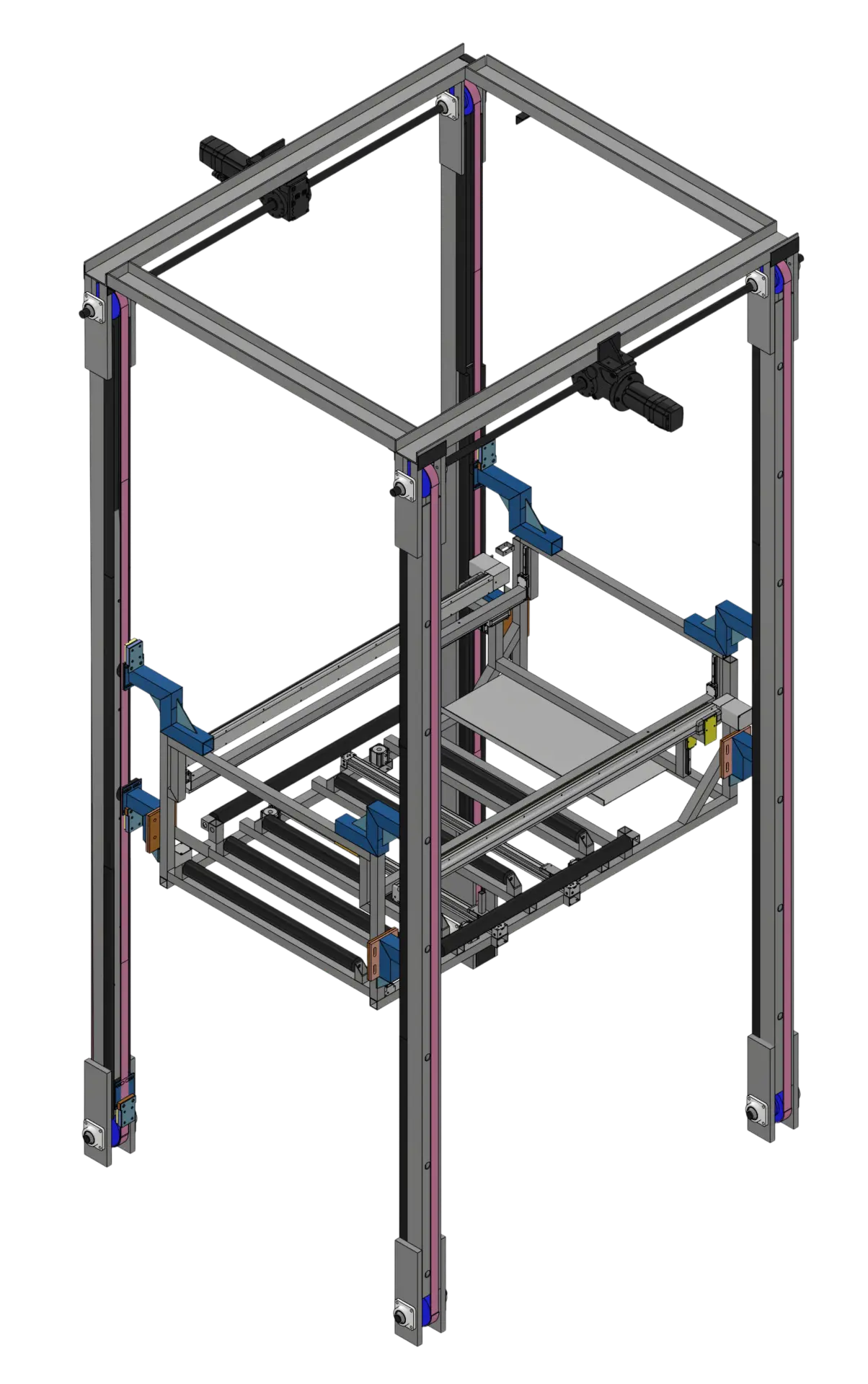

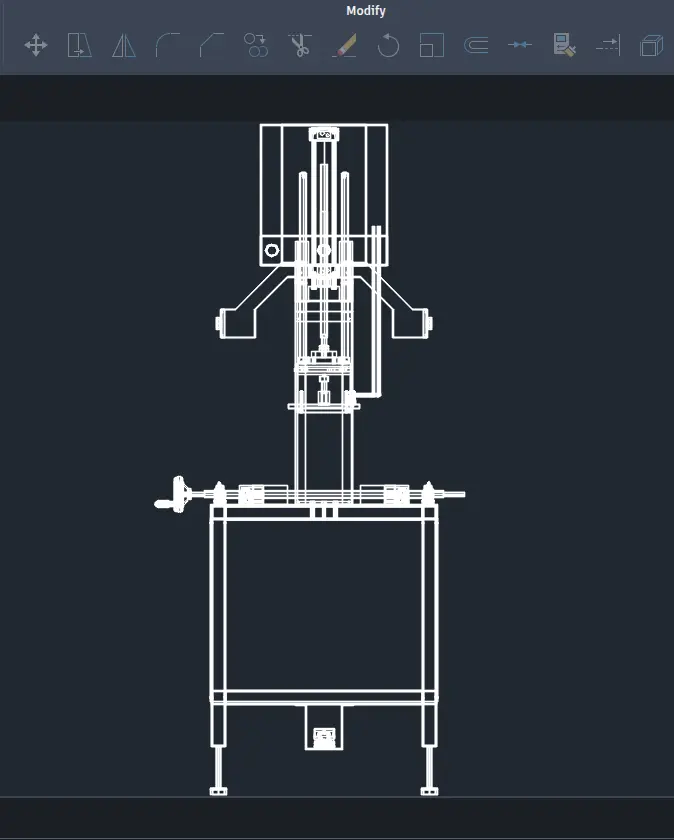

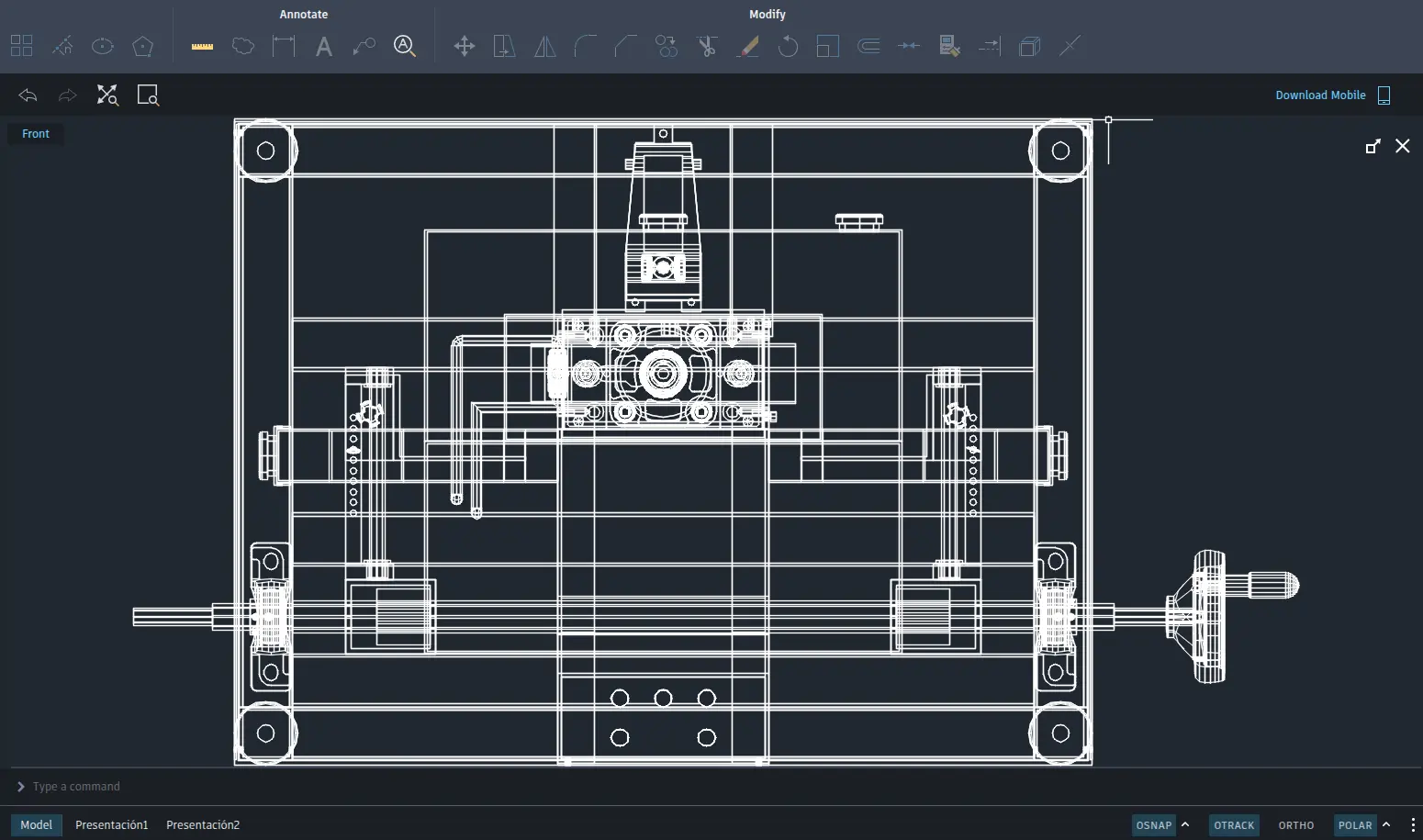

Technical Development

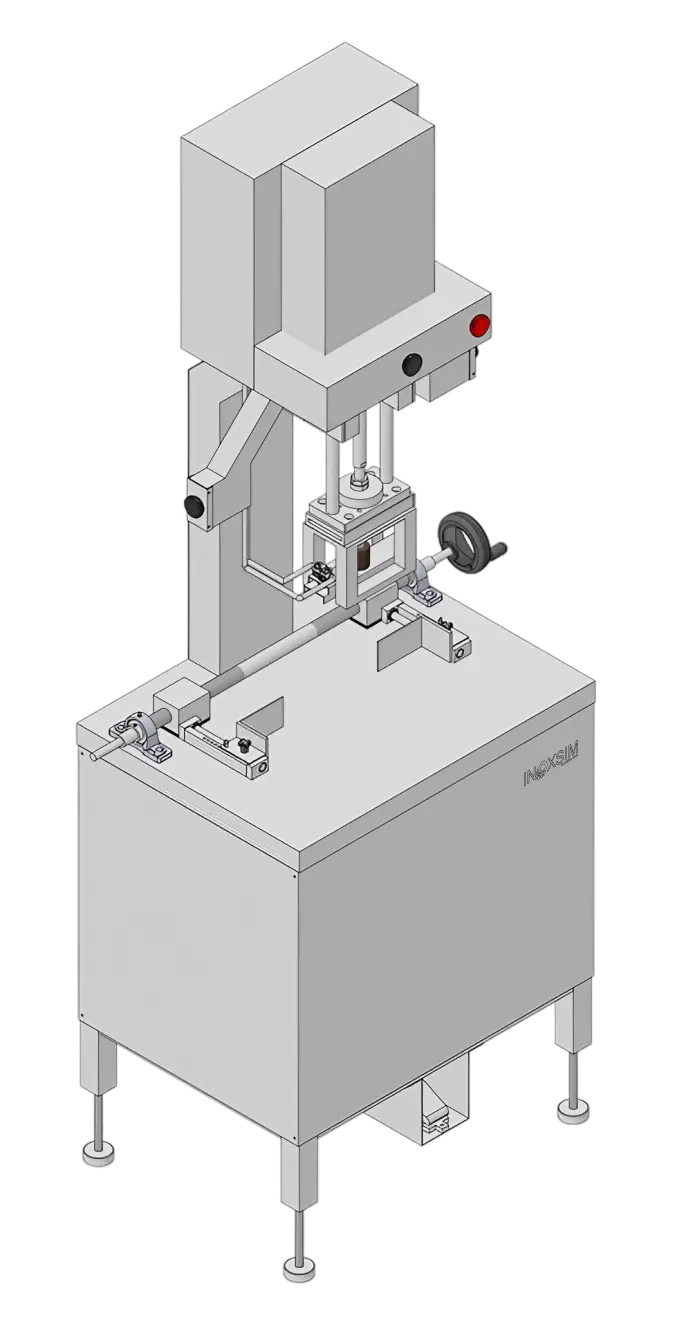

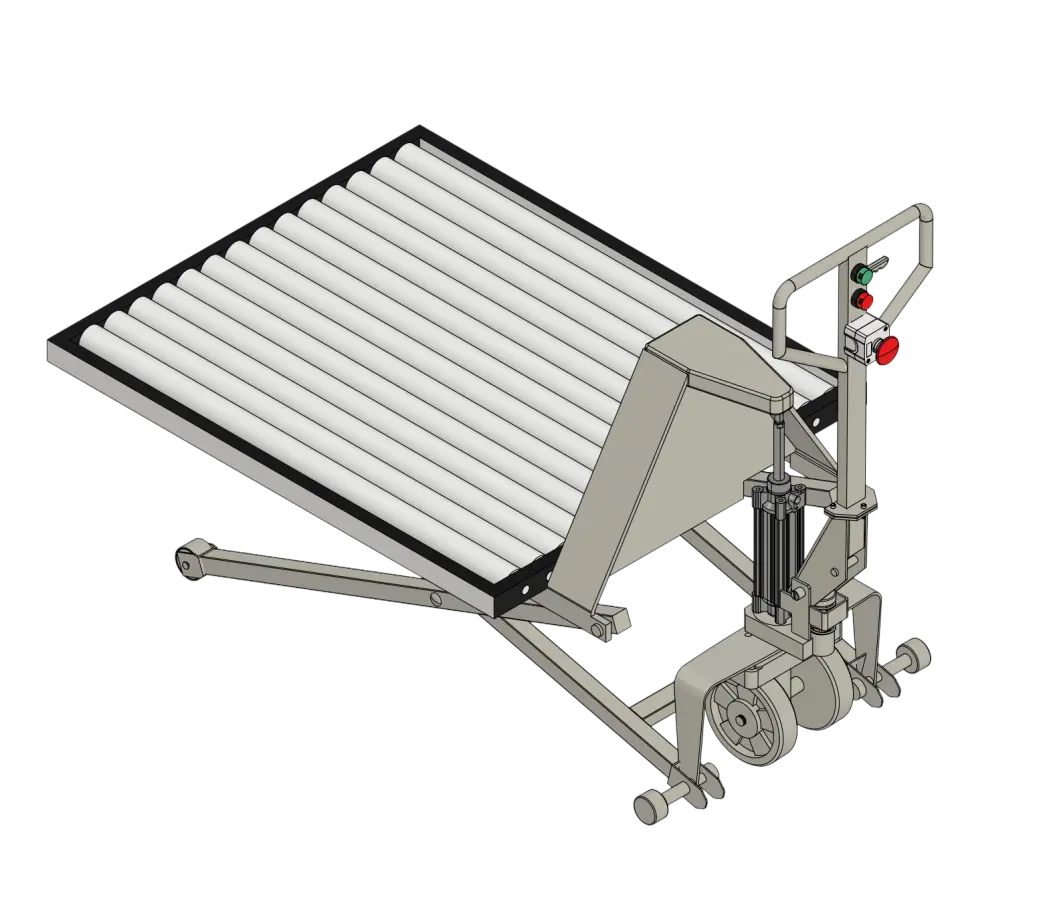

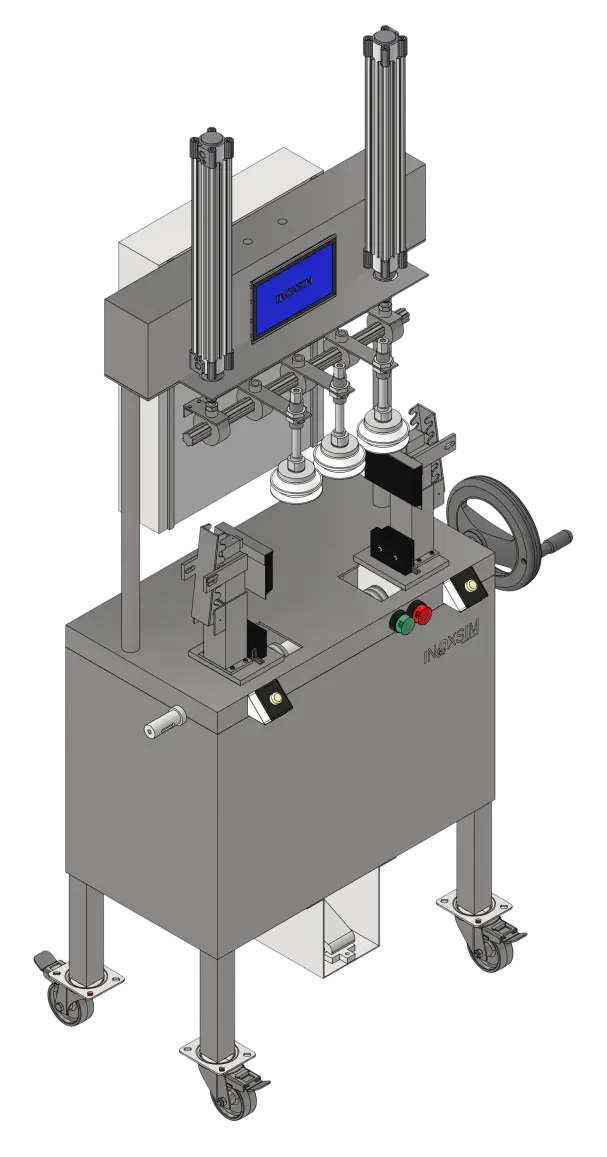

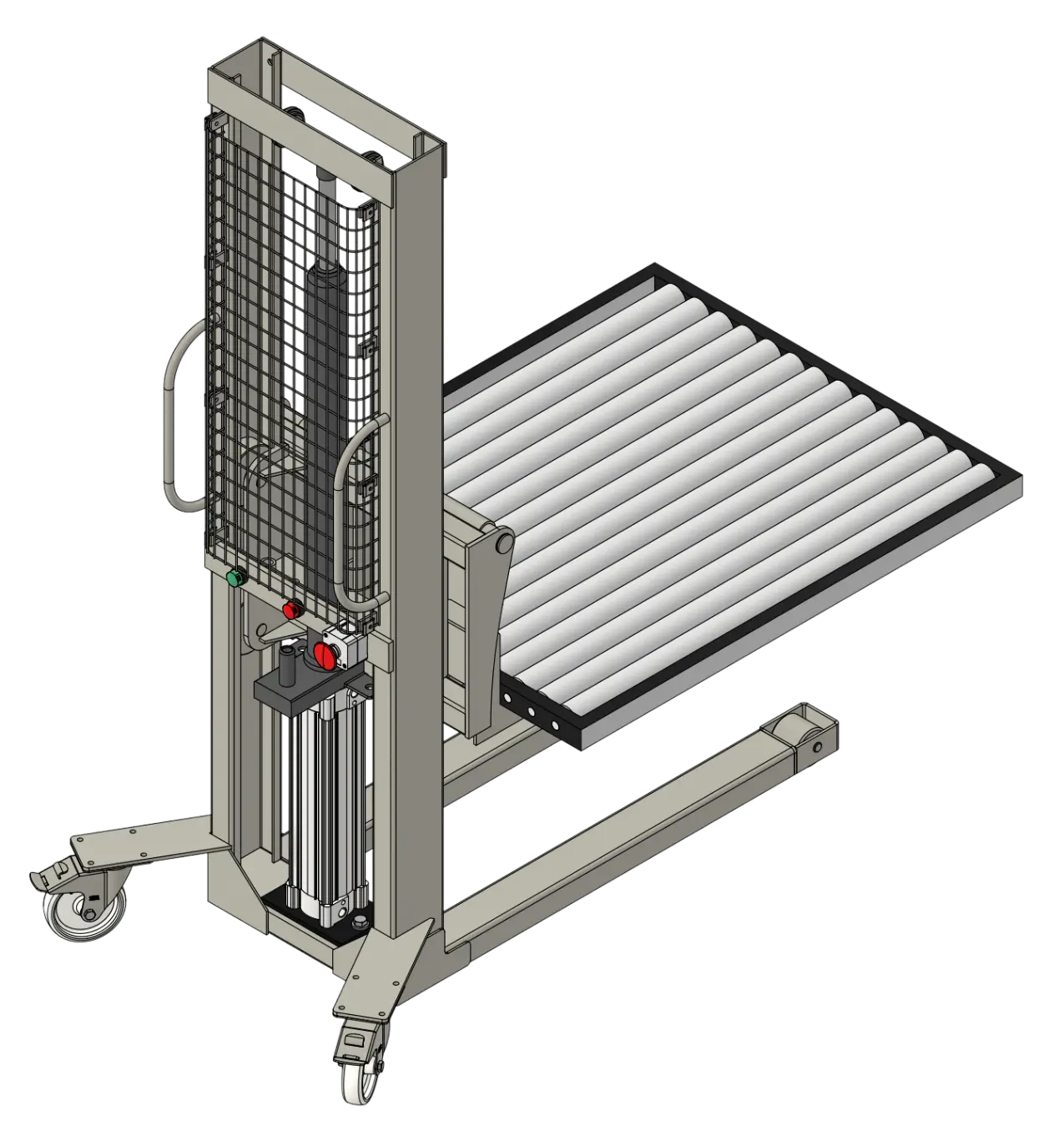

Advanced CAD and simulation tools shape reliable, efficient solutions.

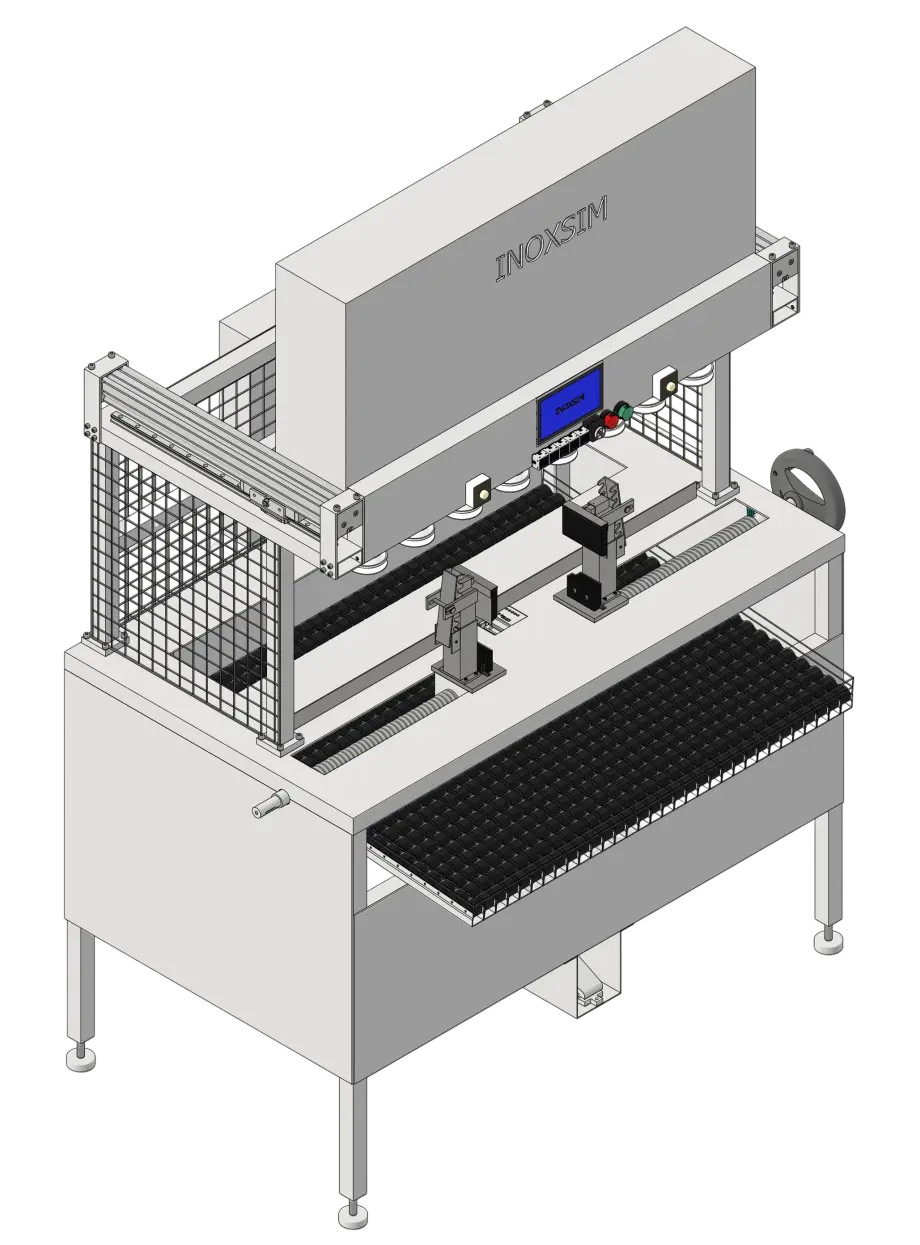

Manufacturing Excellence

Precision crafting with focus on quality, durability and adaptability.

Smart Integration

Seamless implementation ensuring minimal disruption to operations.

Continuous Support

Remote monitoring and rapid response keep your systems performing.

Issue tracking

you’ll enjoy using

Create tasks in seconds, discuss issues in context, and breeze through your work in views tailored to you and your team.

Parent and sub-issues. Break larger tasks into smaller issues.

Automated backlog. Linear will auto-close and auto-archive issues.

Custom workflows. Define unique issue states for each team.

Filters and custom views. See only what’s relevant for you.

Discussion. Collaborate on issues without losing context.

Issue templates. Guide your team to write effective issues.

List and board

Switch between list and board layout to view work from any angle.

Make it yours

Quickly apply filters and operators to refine your issue lists and create custom views.

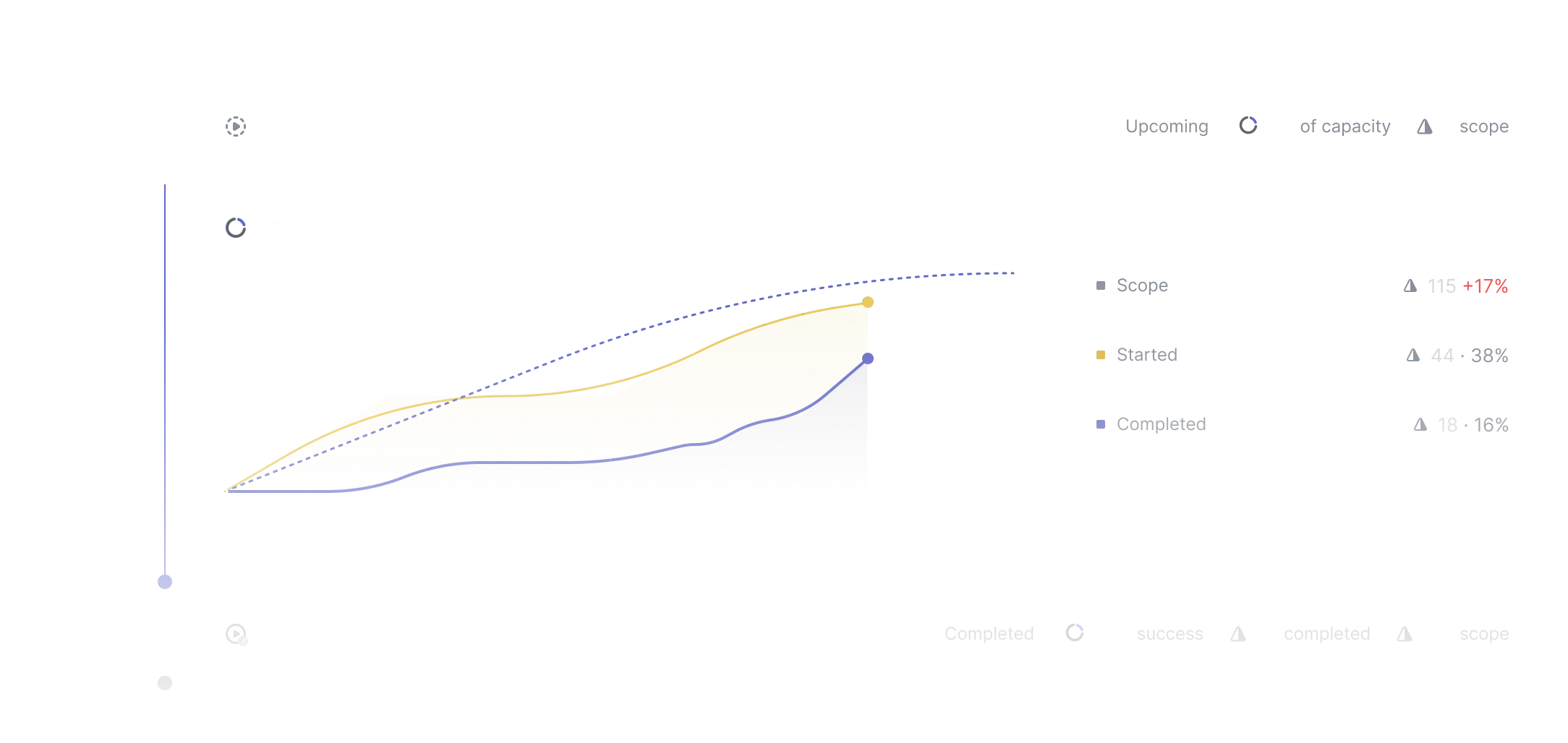

Build momentum

with Cycles

Cycles focus your team on what work should happen next. A healthy routine to maintain velocity and make meaningful progress.

Automatic tracking. Any started issues are added to the active cycle.

Scheduled. Unfinished work rolls over to the next cycle automatically.

Fully configurable. Define start date, end date, duration, and more.

Predict delays. Get warnings for at-risk cycles.

Scope creep. Understand which issues are added mid-cycle.

Be prepared. Schedule work in advance with upcoming cycles.

Building a

timeline together

Our engineering principles guide every project from concept to completion. Each step connects seamlessly to the next, ensuring a complete and effective transformation of your food production processes.

Full immersion in your processes reveals the optimal path to transformation.

Collaborative design shapes solutions that fit your exact needs.

Engineering innovation brings concepts to life with precision.

Crafting your solution with attention to every detail.

Seamless implementation with minimal production disruption.

Fine-tuning performance while training your team for success.

Project updates

Keep everyone up-to-date on the health and progress of projects.

Focus on the big picture

Explore every company project in one view to easily identify what needs attention.

Transform your food

production potential

Whether you're looking to enhance efficiency, improve worker safety, or modernise your food processing operations, we want to understand your unique challenges. Share your production goals with us, and let's explore how our experience-driven solutions can help you achieve them.

Contact us